We create value

with our experience

and specialization

Incomac is not only a company. Incomac is a group of people that add value to the company itself and encourage professionalism every day. Incomac is a group of people that help us to promote the technological tradition and vitality of the Italian engineering, by creating drying systems. Our technicians are experienced both in the air-conditioning and the heat-treatment field. They develop drying systems for any type of wood, from conventional to condensation drying kilns, from kilns for specific heat-treatments to steaming chambers. We aim to build with our customers relationships of trust that get stronger over time. Therefore, our Sales Department is always available for them. Qualified sales agents and dealers support us in submitting our offers both in Italy and in foreign countries. Our factory is like a lab, where experience and innovation melt and blend into one, enabling us to develop resistant and high technology systems. Our kilns are built in full compliance with safety regulations.

Mission

“To be a driver of change in the drying sector by creating sustainable value through the most advanced technologies and by promoting energy savings, creating a lasting partnership with our stakeholders.”

Vision

“We believe in the values of sustainability and human resource empowerment, striving every day to provide reliable and long lasting technological solutions. These will be the keys to becoming the benchmark in our industry.”

We build

turnkey

drying systems

We help you choose the best drying system for your needs

We need to keep up with technology in order to preserve our solid experience and expertise in developing drying systems. We believe in the future and future developments, therefore we are always ready to make structural changes to our processes and projects. We invest in research and development in order to give the best solutions to our customers. For this reason, we are deeply convinced that every project deserves an accurate analysis from different points of view: an analysis that is not only objective-oriented, but also that takes investment optimization and suitability to weather and geographic conditions into account.

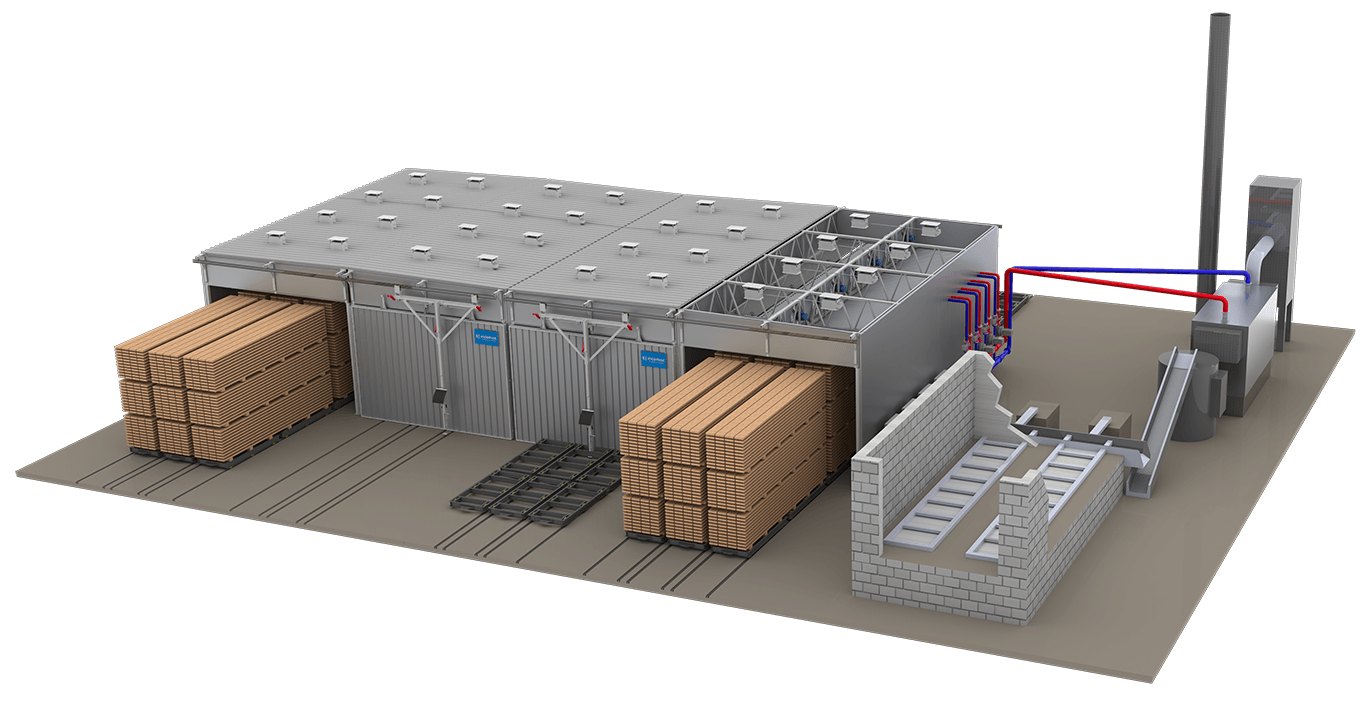

In addition to wood drying systems, we also design and supply:

- the boiler system

- the plumbing system

- the thermal engineering

for the delivery of a fully turnkey project, that fulfils all of the customer’s needs, with the aim of making the entire production aspect efficient in terms of costs and performance.

Industry 4.0 control systems: the aim is to increase quality and productivity

Our systems are efficient, easy to use, and they help you to completely control and monitor the production processes. New additional technologies supervise and increase quality and production performance of our kilns, by making use of data acquisition and remote control. The electronic control system features a weekly program for managing and optimising consumption. Information is available to the operator who constantly monitors all of the process functions thanks to remote control, predictive maintenance, consumption control and constant connection to the headquarters.In order to monitor the energy consumption of the kiln, the management system is set up to acquire all of the data on electrical and thermal consumption. The acquisition of all of the main control parameters (climate and wood moisture) is digital and this, unlike the more commonly used analogue acquisition method, makes the system more accurate and reliable. The distinguishing feature of our new control systems is the possibility of acquiring the climate and wood moisture data through wireless technology, which simplifies and speeds up the main process start-up operations.

Why you

should choose

Incomac

Performance and consumption-centred technologies

Through our research and development department, we create and develop increasingly evolved software and technology aimed at optimising consumption and at the same time accelerating the drying process, preserving the quality of the treated product.

Expert consultants for the realization of custom-made projects

We support our customers in the analysis of their needs and in the search for the most suitable solutions. We aim to guarantee both the highest qualitative and investment performances.

Systems designed for sustainable consumption

We respect the environment, even when we are developing our kilns. Our models ensure maximum efficiency with minimal energy consumption.

Ongoing training activities for our customers

We provide ongoing training opportunities for our clients periodically, both on technology of their drying systems and new technologies, so that we can all keep ourselves up to date and grow together.

Kilns installed in 95 countries

We have installed more than 10.000 kilns worldwide. Experience and reliability are part of our calling card.

Kilns made in Italy

We listen to our customers’ needs and create wood drying, steaming and heat treatment systems. Functional, high quality, efficient and technologically advanced, certified Made in Italy.