tag

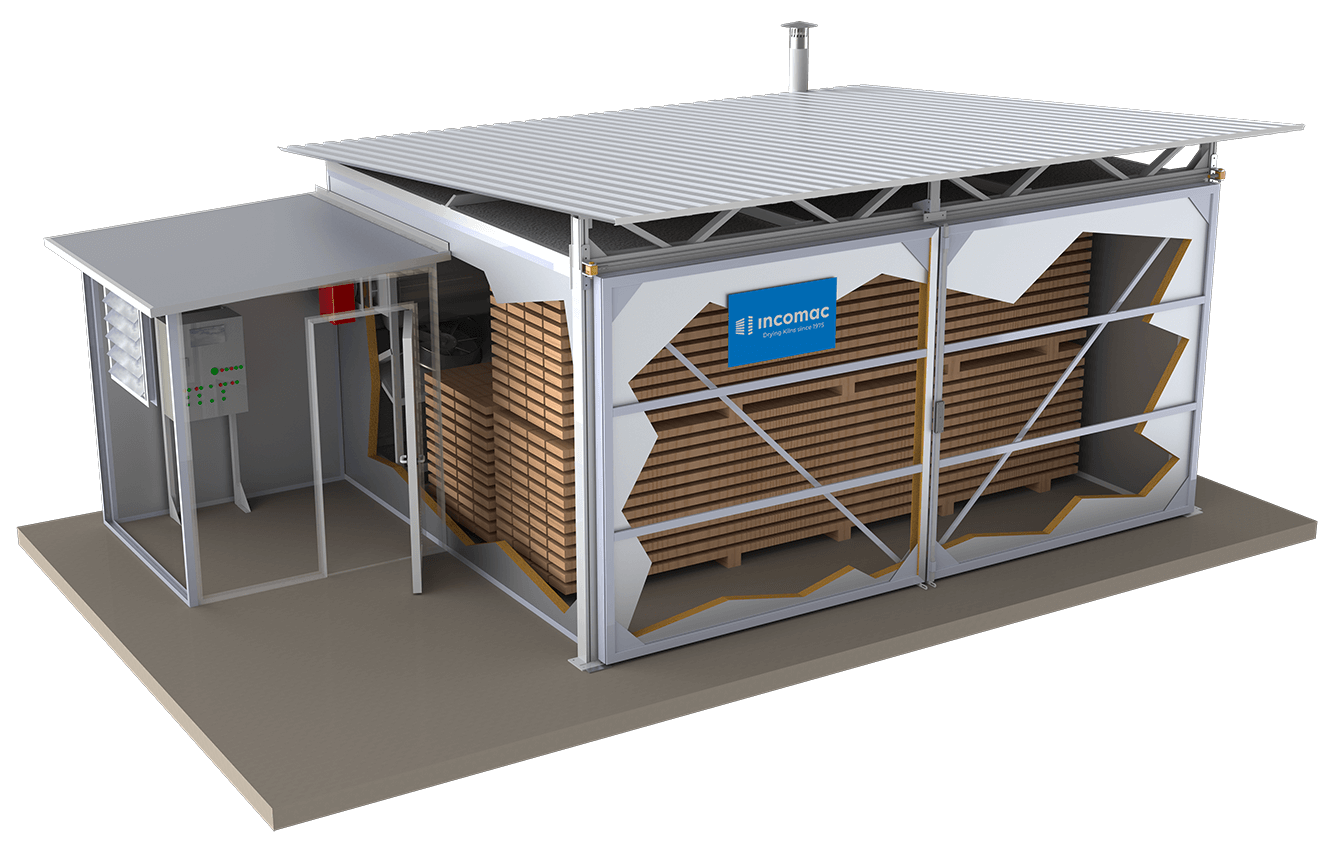

Secadero de gas natural, LP, diesel o renovables

Secadero de calentamiento

directo con quemador

Facilidad de mantenimiento

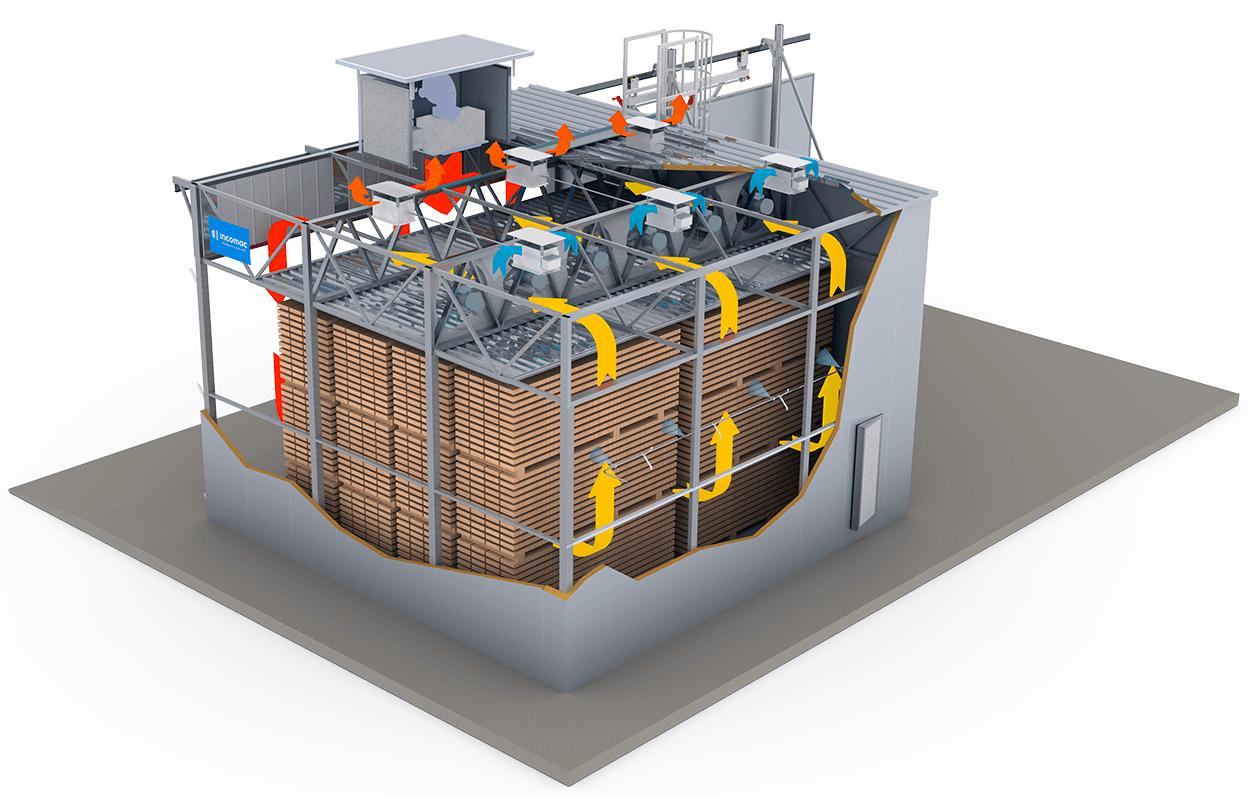

Aumento rápido de la temperatura en la cámara, adecuado para ciclos cortos de tratamiento térmico

Wood drying kiln with direct heating; the chambers already include a burner and do not need an external boiler to be installed. The direct heating system ensures an initial reasonable investment and consumption optimization. The TAG wood drying system is a variation of traditional systems. Drying is carried out using the same principle: partial exchange of moist inside air with outside air. There is no direct contact between combustion and chamber. It is therefore a wood drying system offering high safety and low consumption. With diesel oil feeding, a burner, external to the chamber, burns the fuel in a combustion chamber connected to stainless steel tubes that serve as heat exchangers. Thanks to the special shape of the chamber, the produced heat is recovered and the fumes are expelled externally at a low temperature. With natural gas or LPG feeding, we use direct fired burners that convey the heat directly into the chamber without expelling the fumes externally. Also, this system saves energy thanks to the possibility of modulating the delivered power proportionally to the process needs.

Scarica il nostro catalogoCampo di applicazione

Softwood

Hardwood

Exotic woods

Pallets

Beams

Lamellas

Firewood

Junior version

The TAG drying system is also available in the junior version, to fulfil the demands of dryers with contained capacities: 5, 10, 20 m3. Junior models are the best solutions for operators who need high-quality drying of small amounts of wood. Since these systems are small-sized, they can also be easily installed inside the factory, as an integral part of the production line. Rails and trolleys make loading fast and easy.